1

/

of

9

Rigging Level 2

Rigging Level 2

Course Type

Safety Training.

Course Purpose

- This course is for a worker whom utilizes rigging (lifting) equipment for material lifting and handling.

- This course is suitable for students whom are preparing to challenge their Crane Operator Level A Assessment with Fulford Certification (rigging knowledge and rigging calculations).

- Lifting equipment includes: chain slings, wire rope slings, synthetic slings and a variety of rigging hardware.

- This course DOES NOT include training to operate powered lifting machinery.

Training Method

In-person.

Class Size

3 - 16 students.

Training Duration

16 hours (2 days).

Training Locations

- At OOSHEW's Surrey Training Facility.

- In-person training at the customer's location (Alberta, British Columbia).

Customer Requirements

Rigging equipment and load for practical lessons when the training is held at the customer's location.

Student Requirements

Wear the required Personal Protective Equipment (provided by student):

- PPE as per the training location requirements.

- Safety boots, hard hat, high visibility vest/jacket/overall.

Training Certification

Digital training card as proof of training, includes hyperlinked class photos and course material. Valid for 3 years.

Bonus for Large Employers (50+ students): Access to OOSHEW's robust training database (training records from your employees and your subcontractors).

Course Outline

Literature

- Internet based with rich multimedia information, accessible on computer or mobile device (Apple, Android).

- Start by setting up a free account Click Here to Get the Mobile App

Theory Lessons

- Applicable OHS Regulations (Federal, Provincial).

- Applicable CSA standards and ASME standards.

- Responsibilities for the Rigger.

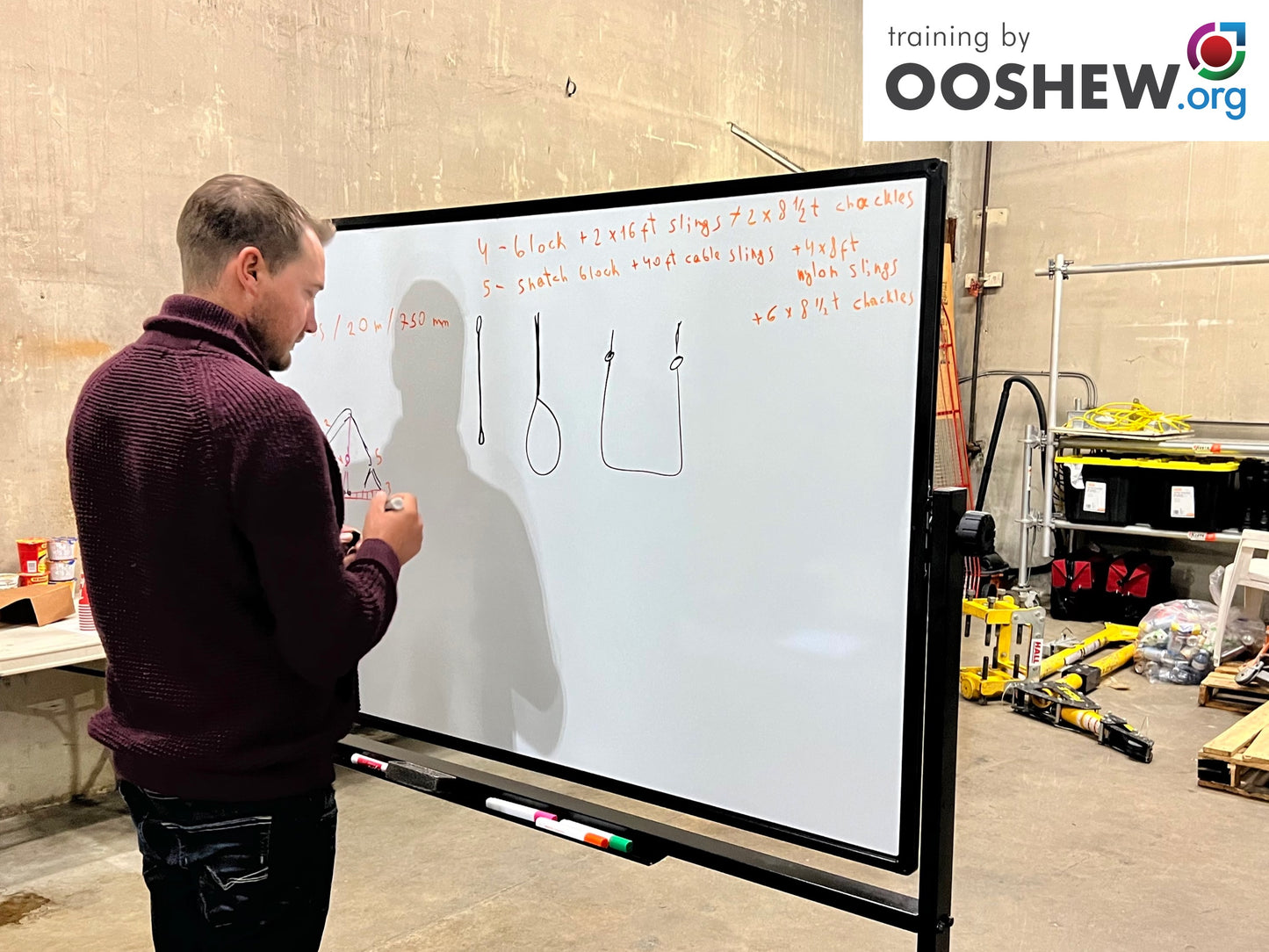

- Specifications, inspection criteria and rejection criteria for synthetic slings, chain slings and wire rope slings.

- Specifications, inspection criteria and rejection criteria for shackles.

- Safety factors for lifting equipment.

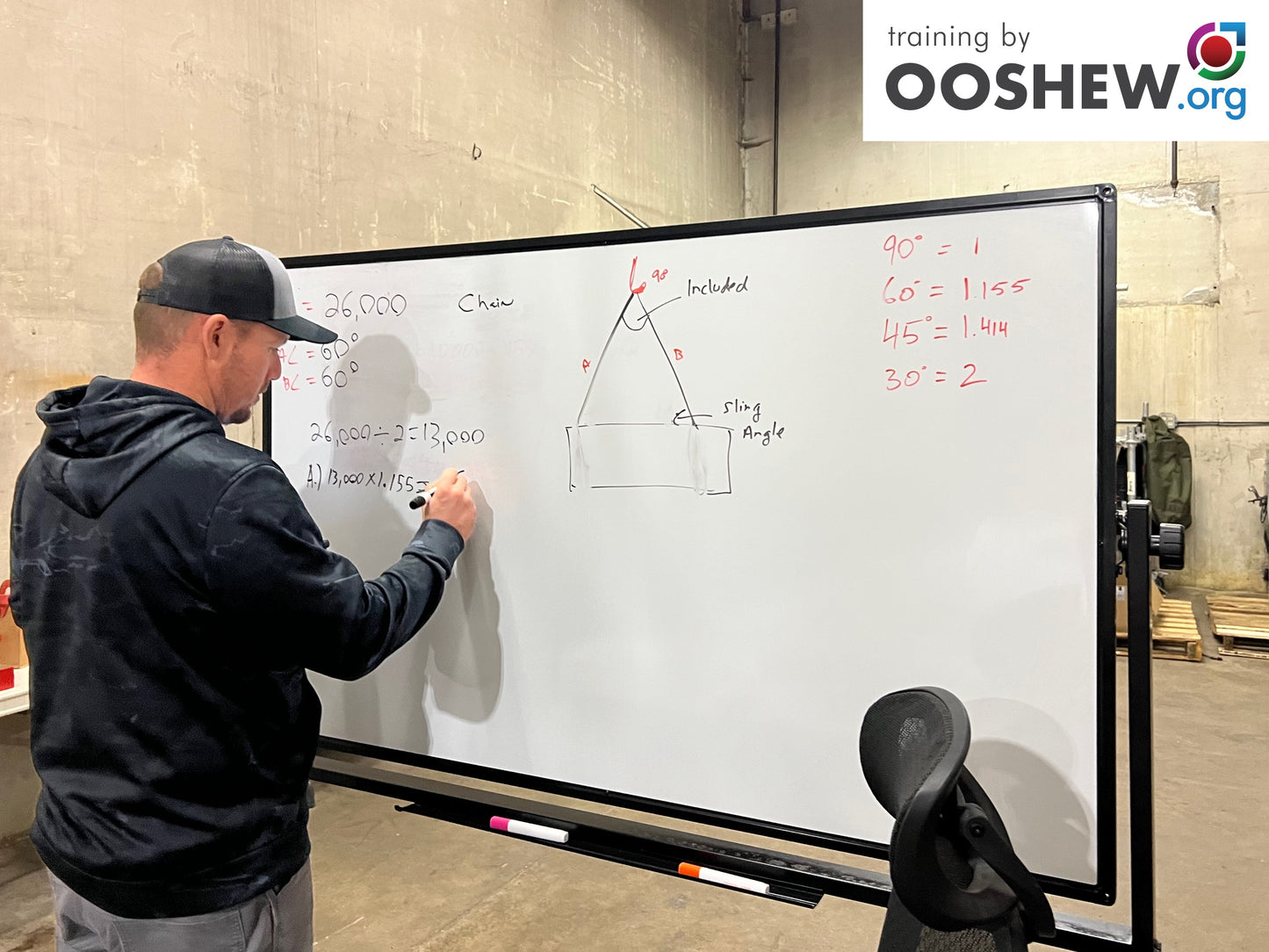

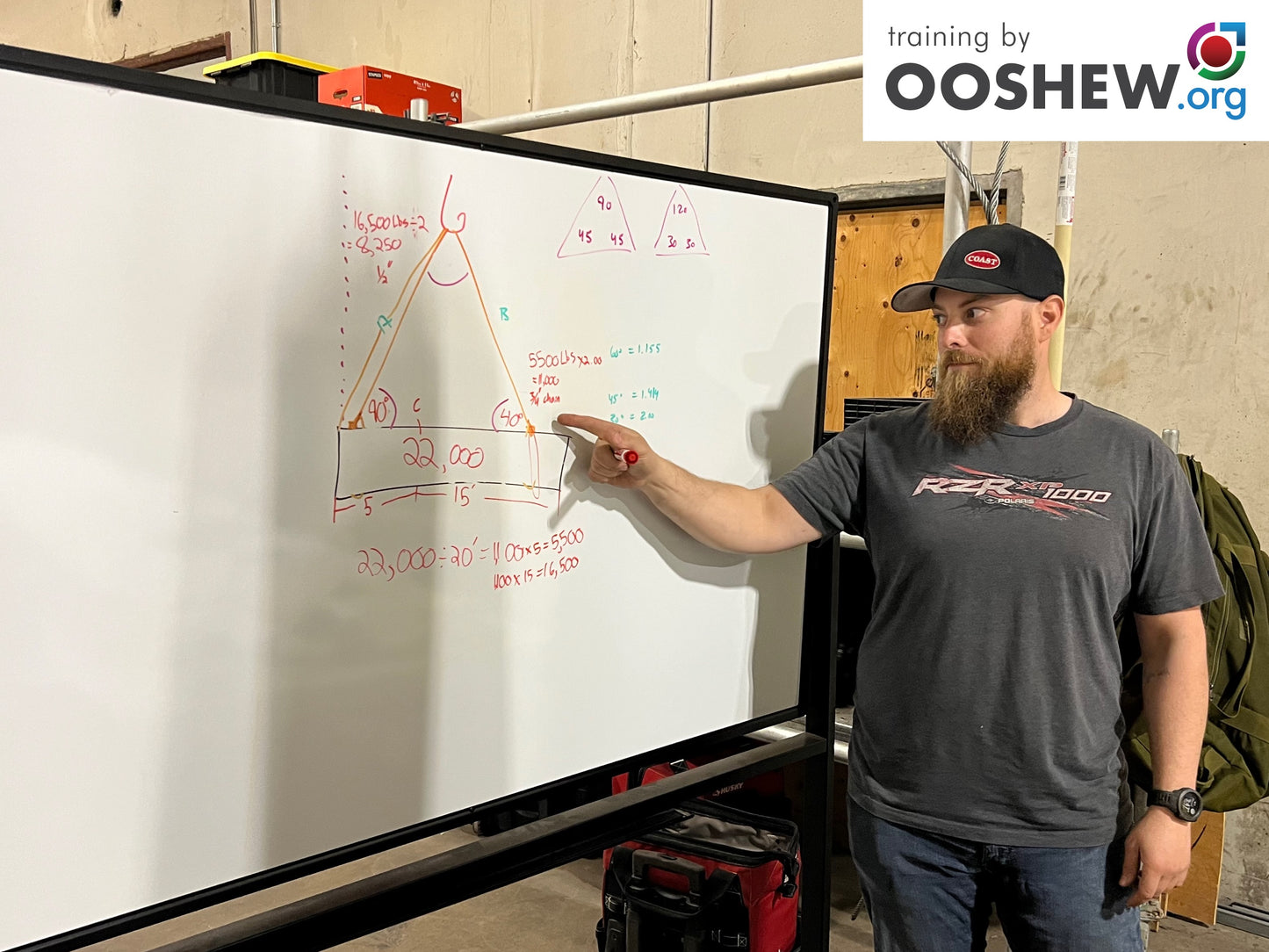

- Sling tension factors.

- D/d ratios.

- Workplace safety and safe rigging procedures.

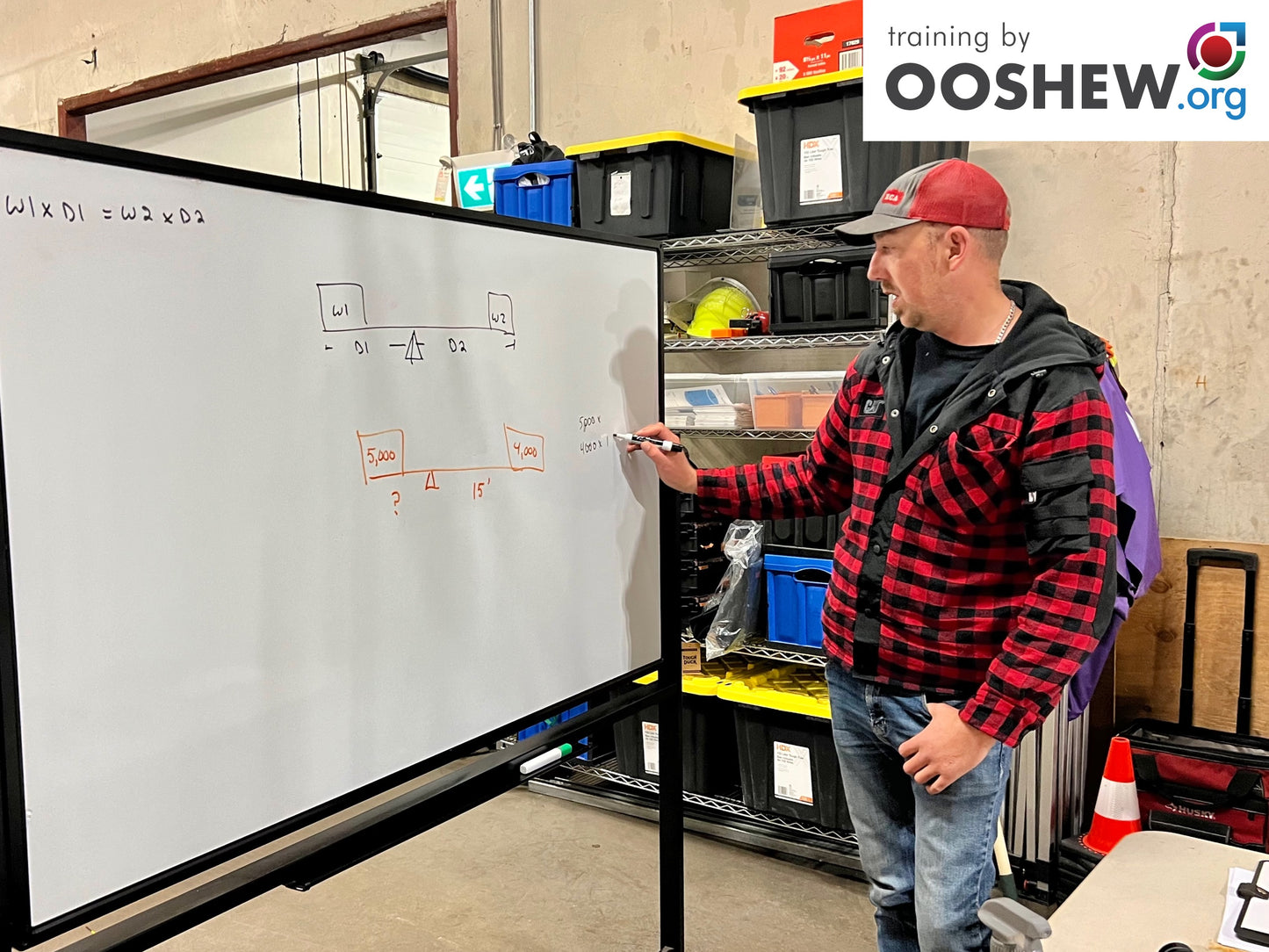

- Load calculations as required by the Fulford Certification Level A and Level B Assessment.

- Specifications, inspection criteria and rejection criteria for additional rigging hardware:

- Chain fall,

- Lever hoist (come-along),

- Lifting beam and bar,

- Lifting clutch (for concrete precast structures),

- Lifting hook,

- Lifting eye bolt,

- Master link,

- Plate clamp,

- Swivel hoist ring.

Documentation Lessons

- Completing a Hazard & Risk Assessment.

- Completing a Lift Plan.

Practical Lessons

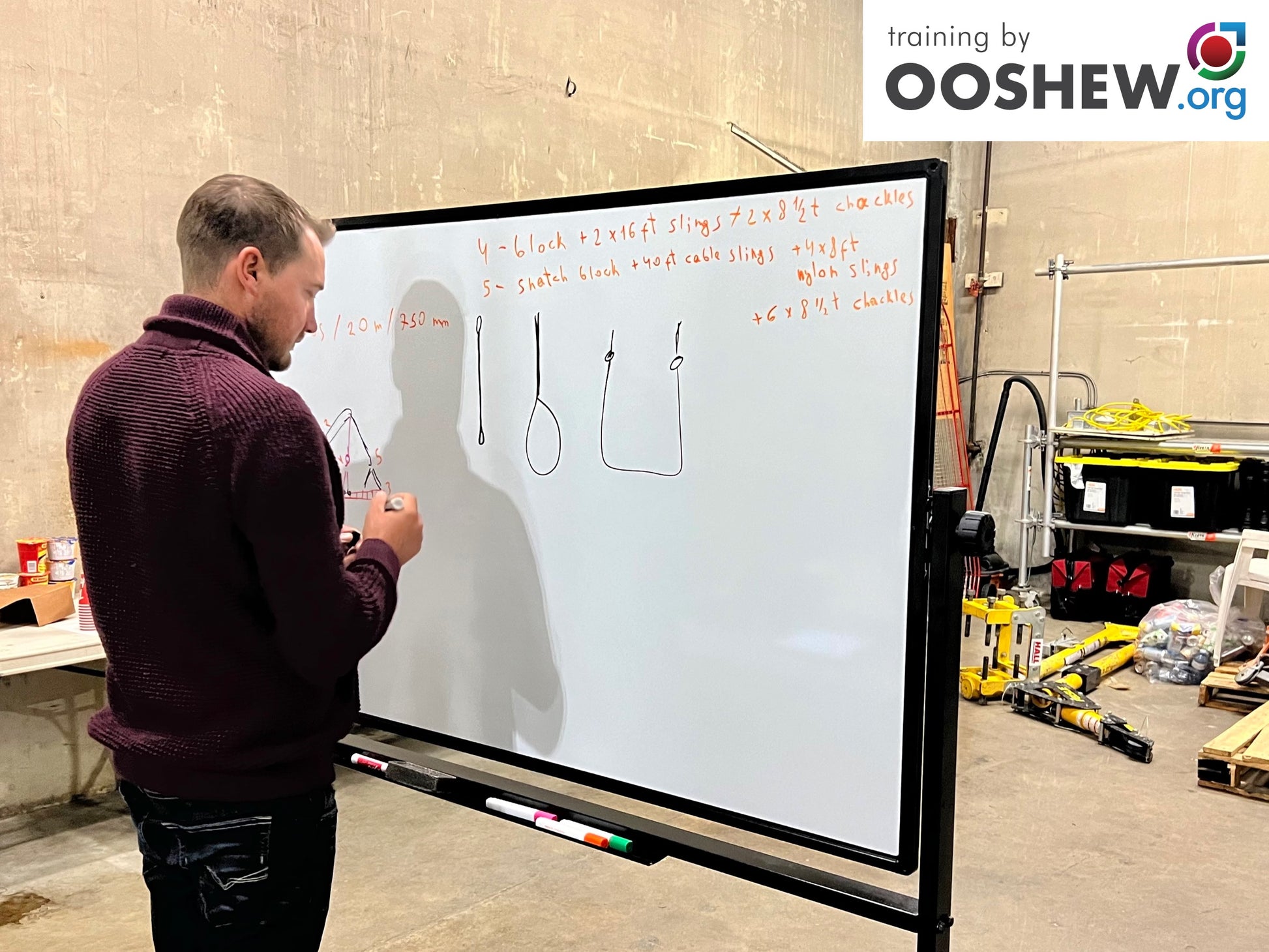

- Inspecting and application of lifting slings (chain, wire rope, synthetic).

- Inspecting and application of shackles.

- Application of common rigging knots (for tagline).

- Hand signals.

- Lift planning.

- Practical lifting of loads.

- Inspecting and application of the additional rigging hardware.

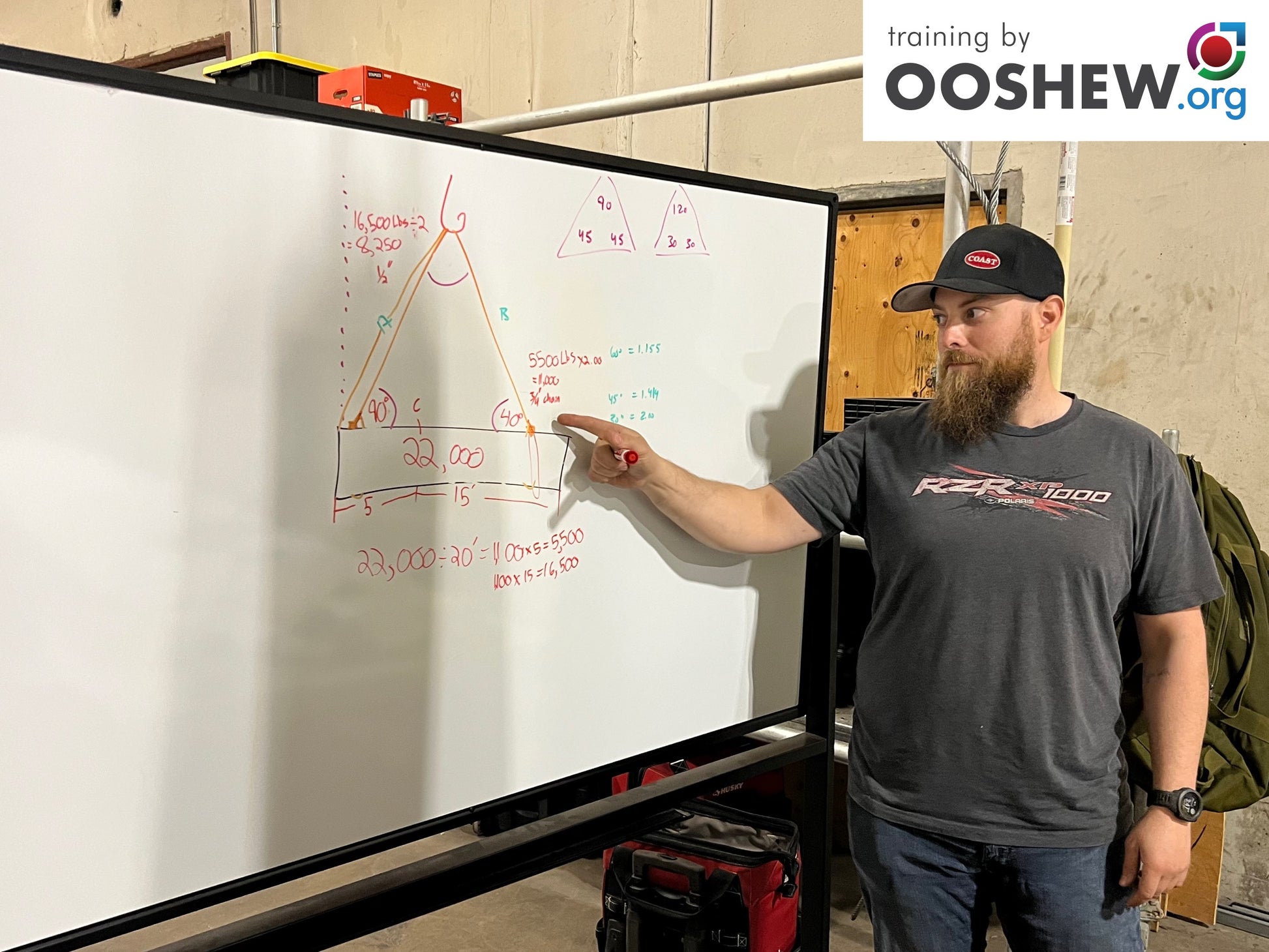

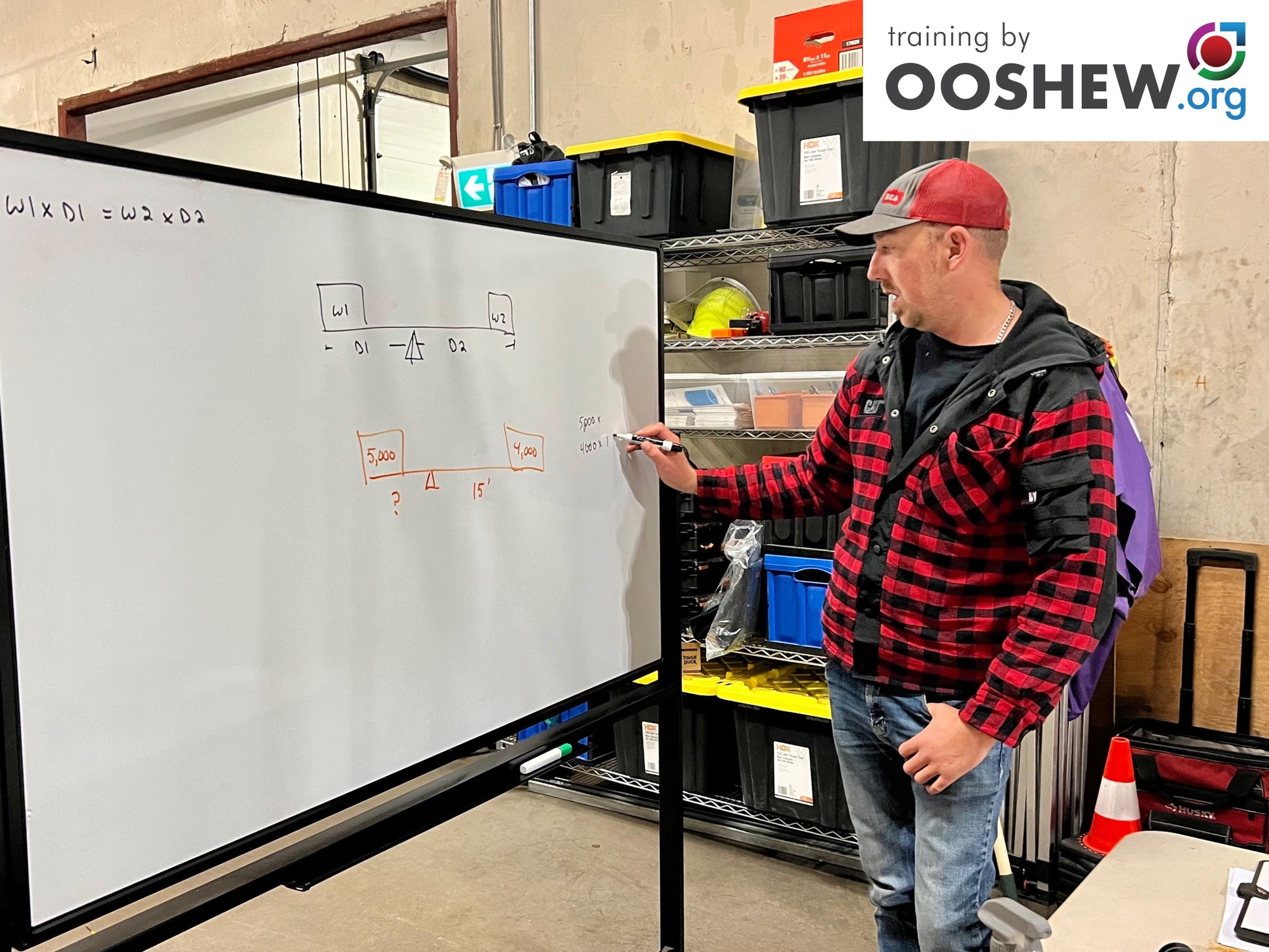

- Calculating load sharing.

- Calculating load balancing.

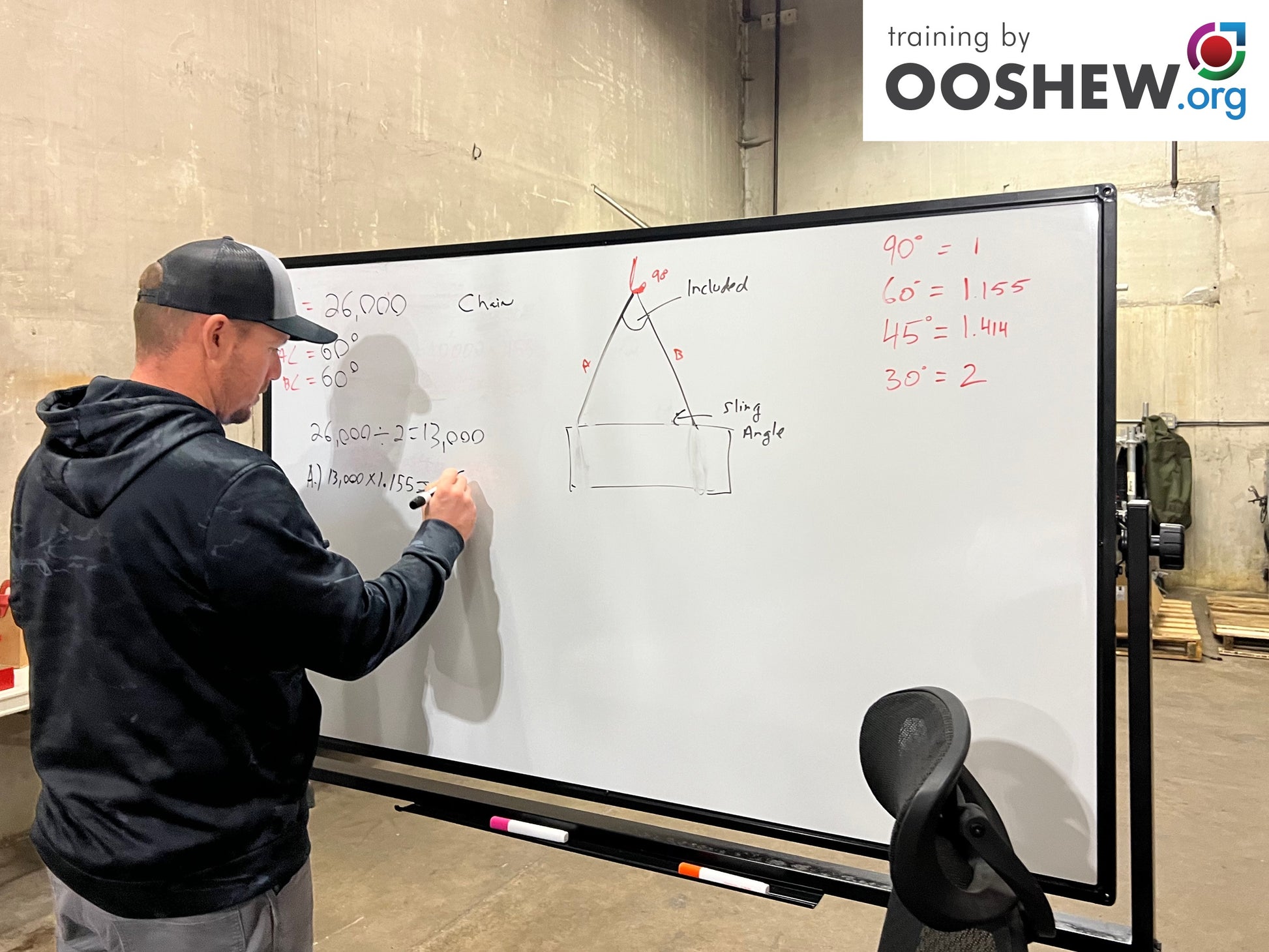

- Calculating sling tension.

Pricing

- Drop-In Class at OOSHEW Facility: $600.00 per student.

- Private Group Rate at OOSHEW Facility: $4,800.00 (first 8 students) + $500.00 per additional student.

- Private Group Rate at the Customer's Location: $6,000.00 (first 8 students) + $500.00 per additional student.

- Platinum Members: 15% discount.

- Additional Fees: Out of town travel expenses and accommodations when applicable.

Share